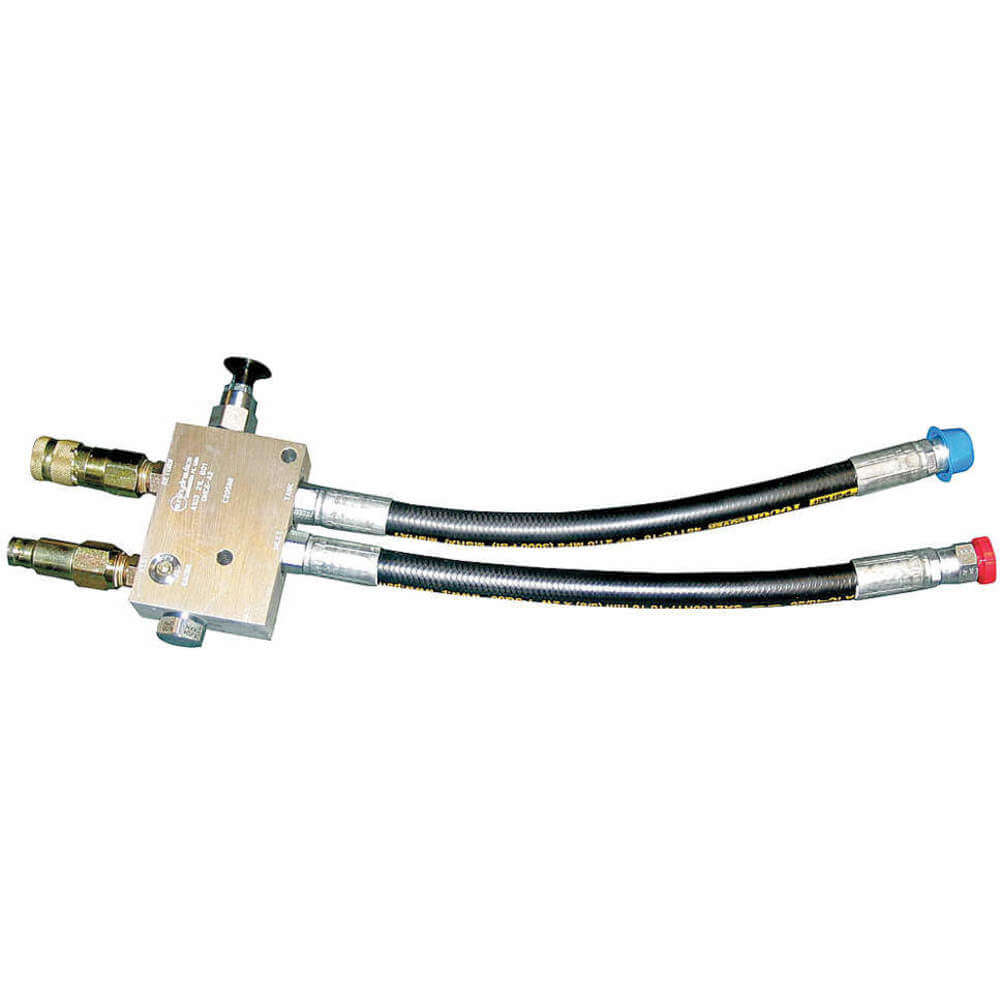

Greenlee Flow Control Remote Valves:

- They feature an open / closed centre hydraulic system for facilitating single / multi-directional flow, respectively.

- These flow control valves have metal construction for structural rigidity and corrosion resistance.

- Their ergonomic design resists dirt, dust and small particles to block the flow of fluid.

- They can withstand temperatures ranging up to 140 degrees F.

ICS Hydraulic Flow Control Valves:

- They have open / closed centre hydraulic systems to allow single / multi directional flow, respectively.

- These valves come with a 3/4 inch-8 SAE tool return port for user comfort and time-saving.

- They feature steel & rubber construction for structural rigidity and leakproof operations.

- These flow control valves are equipped with a flow adapter for increased flexibility and reduced downtime.

£ GBPChange Country

£ GBPChange Country