- Lock washers work in conjunction with threaded fasteners (like nuts) to prevent loosening.

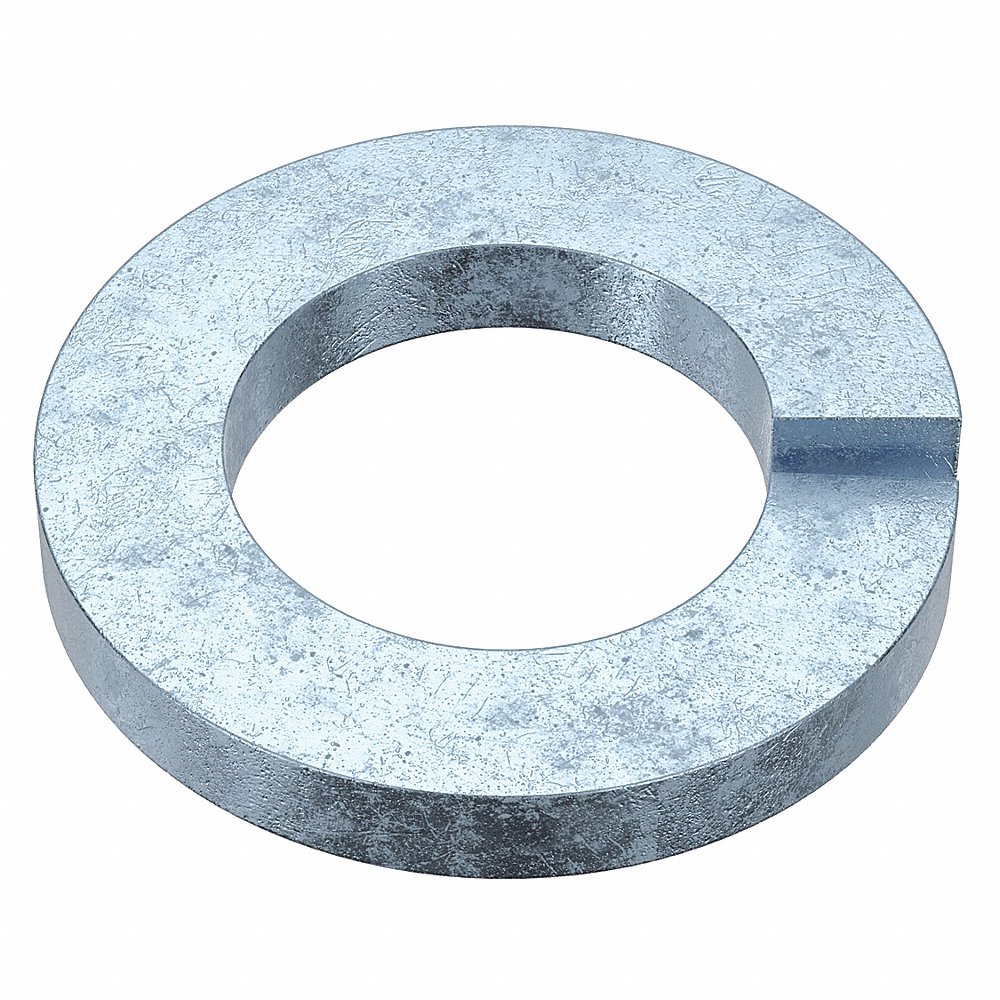

- Helical-shaped lock washers, spring lock washers & split lock washers get activated at the slightest pressure and offer a spring action.

- Selected lock washers have serrations on their external grip surfaces (top & bottom, or just the top) for extra gripping power. This prevents loosening / shifting due to high vibration.

- Some Belleville spring lock washers feature smaller outside diameters compared to standard spring lock washers for fitting under socket head cap screws.

- Lock washers conform to standards like ASME (American Society of Mechanical Engineers), DIN (German Institute for Standardization), military specifications and NAS (National Aerospace Standards).

- Most washers come in packs containing multiple pieces for easy replacement.

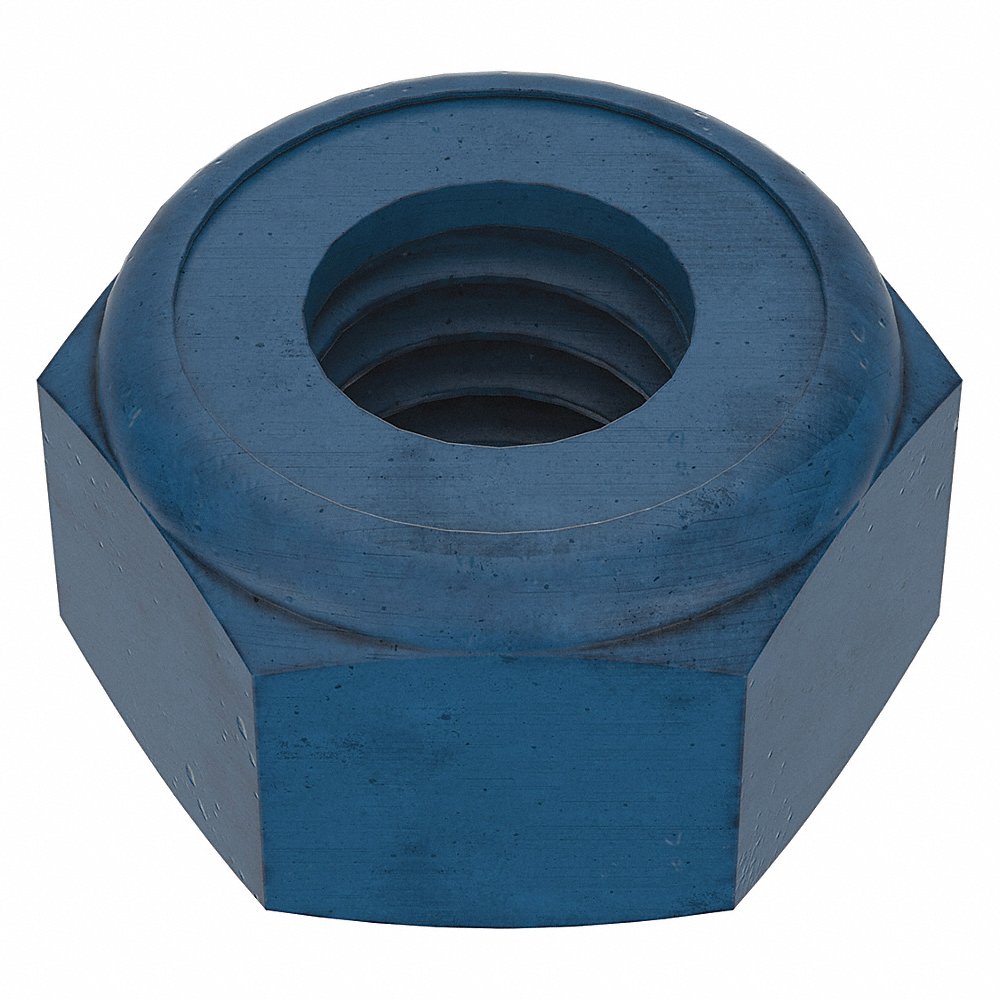

Disc-Lock Washer Bolts:

- Disc-Lock washers use the wedge-locking system for preventing the loosening of bolts & maintaining joint integrity in high-stress, corrosive & vibration-sensitive applications.

- Disc-Lock washers feature two pre-assembled washer-shaped pieces having inclined cams on one side and ridges on the other side. After installation, these two cam sides mate together and get placed between the nut & the joint material.

- When the nut attempts to rotate loose upon vibration, the interlocking cams & the non-slip ridges of these Disc-Lock washers create a jamming effect & prevent loosening.

- They have Delta-Protekt coating for high corrosion resistance.

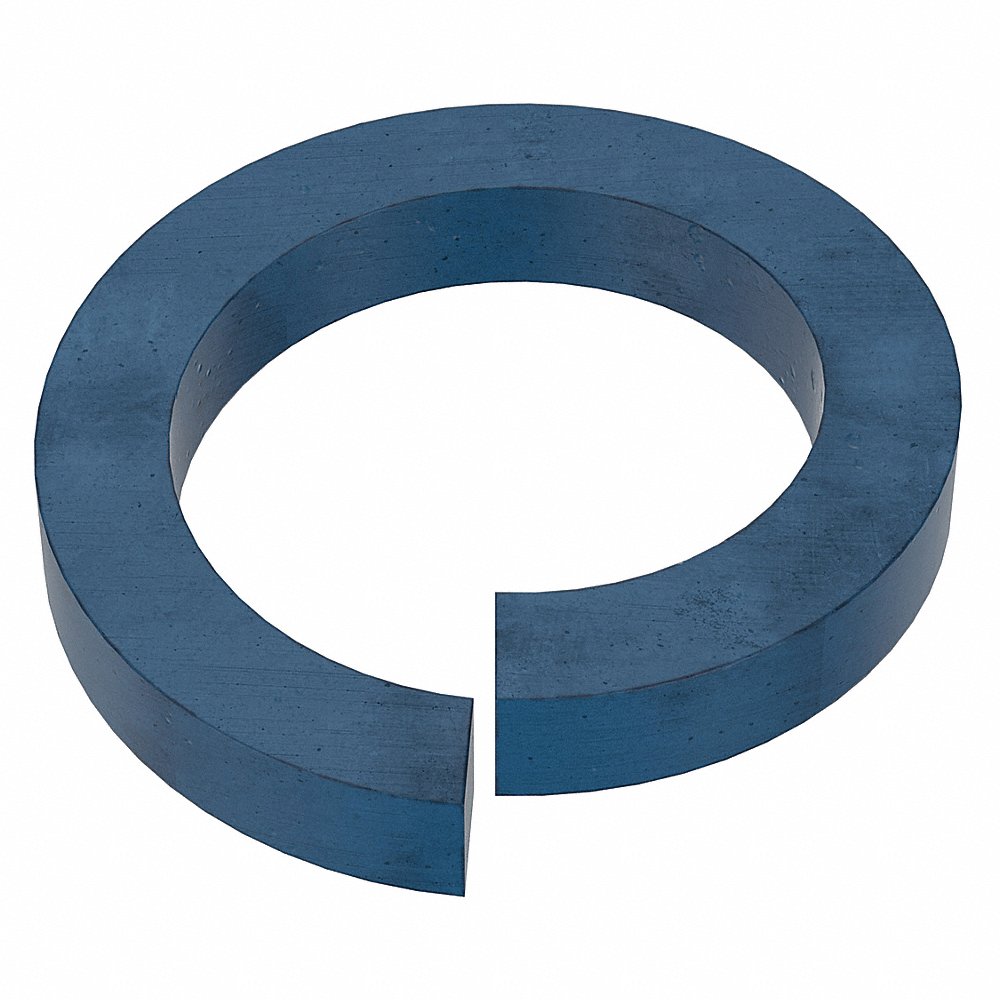

Metric Blue Split Lock Washers:

- These split lock washers have high collars for more holding surface.

- They have a blue-coloured coating for easy metric identification.

Fabory Lock Washers:

- These lock washers are made of spring steel, stainless spring steel, stainless steel, aluminium, bronze, phosphor bronze, silicon bronze or steel for use in diverse environments & operations.

- They are available in helical spring, toothed, wedge, conical spring, contact, curved locking edge, curved spring & wave spring styles.

£ GBPChange Country

£ GBPChange Country