Dayton Spider Coupling Inserts:

- They are used with metal jaw couplings for uniform power transmission while maintaining structure and position.

- These Hytrel spider inserts offer excellent oil & impact resistance and are capable of withstanding temperatures ranging from -60 to 70 degrees F.

- Their assembly comprises two jaw hubs and a spider for transmitting higher torque and preventing misalignment (angular & parallel) between the connecting shafts.

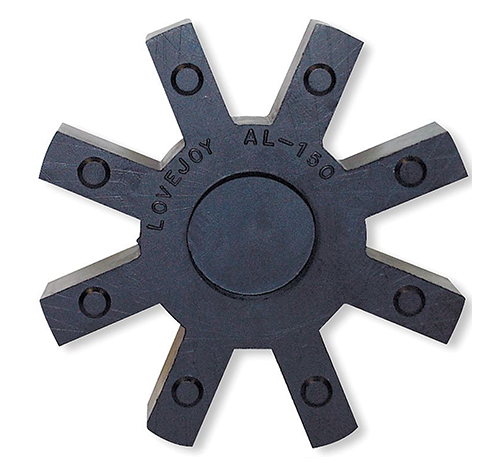

Lovejoy Snap Wrap Spiders:

- These flexible snap wrap spiders permit close shaft separation up to the hub's maximum bore size.

- They have urethane or SOX (NBR) rubber construction that ensures abrasion resistance and protection against dirt, grease & moisture.

- Their snap wrap design allows easy removal of the units without moving the hubs.

Ruland Manufacturing Curved Jaw Coupling Spiders:

- They dampen shocks and accommodate misalignment (angular, parallel & axial) between coupling hubs.

- Their polyurethane construction does not require lubrication and can hold up against dirt, sand, grease, oil & moisture.

- These coupling inserts are used with coupling hubs and can handle torque ratings up to 8000 RPM.

£ GBPChange Country

£ GBPChange Country